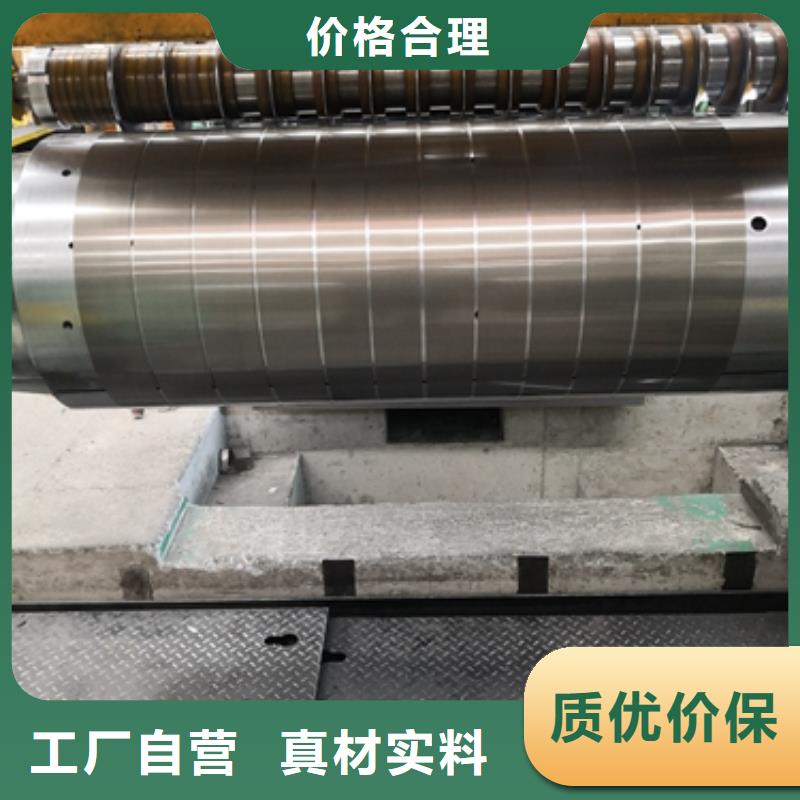

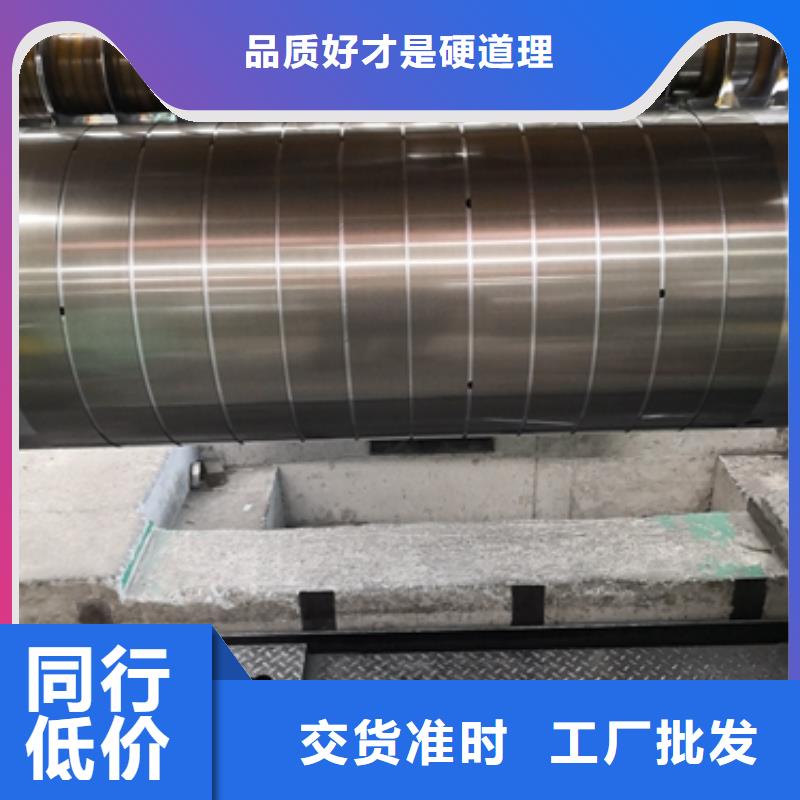

我们的现场实拍视频将带您走进 B27P100硅钢片铁损产品的世界,产品视频细节之美一览无余!

以下是: B27P100硅钢片铁损的图文介绍

电工钢硅钢片硅钢以铁芯损耗(简称铁损)和磁感应强度(简称磁感)作为产品磁性保证值。硅钢铁损低可节省大量电能,延长电机和变压器工作运转时间和简化冷却系统。由于硅钢铁损造成的电量损失占全年发电量的2.5%~4.5%,其中变压器铁损约占50%,1~100kW小型电机约占30%,日光灯镇流器约占15%。硅钢磁感高,铁芯的激磁电流降低,也节省电能。硅钢磁感高可使设计的 磁感(Bm)高、本地铁芯体积小、本地重量轻,节省硅钢、本地导线、本地绝缘材料和结构材料等,既使电机和变压器损耗和制造成本降低,又便于组装和运输。由带齿圆形冲片叠成铁芯的电机在运转状态下工作。要求硅钢板为磁各向同性,用无取向硅钢制造。由条片叠成铁芯或由条带卷绕成铁芯的变压器在静止状态下工作,用磁各向异性大的冷轧取向硅钢制造。此外,要求硅钢具有好的冲剪性,表面光滑平整和厚度均匀,好的绝缘膜和磁时效小。

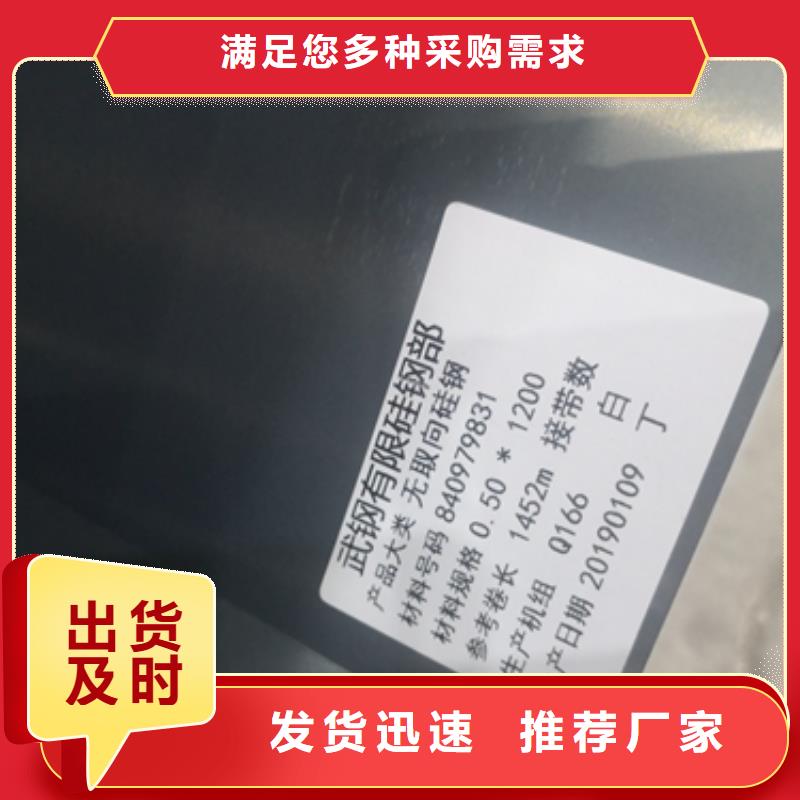

电工钢硅钢片Electrical steel, also known as silicon steel sheet, is an indispensable metal material in the power, electronics, and military industries, and is also the largest functional material in production. It is mainly used as the iron core for various motors, generators, and transformers. Specific total loss (iron loss) is the total power consumed per unit mass of material when the magnetic polarization waveform remains sinusoidal, with a specific peak and frequency. The specific total loss is represented by the symbol P (Jm/f), in W/kg. Example: P1.5/50 represents the specific total loss at a maximum magnetic polarization intensity of 1.5T and a frequency of 50Hz. 3.2 Magnetic Polarization Q/BQB 480-20212 Magnetic polarization intensity refers to the peak magnetic polarization intensity of a specific magnetic field intensity when a sample is subjected to alternating magnetization. Its symbol is J (H), and the unit is T (Tesla). Example: J5000 represents the peak magnetic polarization intensity corresponding to a magnetic field intensity peak of 5000A/m. The material grades in this document are classified based on the nominal maximum specific total loss P1.5/50 (W/kg) at a magnetic polarization strength of 1.5T and a frequency of 50Hz, as well as the nominal thickness of the material. They are further divided into three categories based on product characteristics: ordinary type, stress relief annealing type, and high-efficiency type. Example 1: B35A210 represents a common non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific total loss value P1.5/50 is 2.10W/kg; Example 2: B35AR300 represents a stress relieved annealed non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific total loss value P1.5/50 is 3.00W/kg; Example 3: B35AH230 represents an efficient non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific loss value P1.5/50 is 2.30W/kg. Example 4: 35WW210 represents a normal type WW non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific loss value P1.5/50 is 2.10W/kg. Example 5: 35WH230 represents an efficient WH non oriented electrical steel with a nominal thickness of 0.35mm, and the maximum nominal specific loss value P1.5/50 is 2.30W/kg. The classification and code of insulation coatings shall comply with the provisions of Table 2. Table 2 Classification and Code of Insulation Coatings Type Code Characteristics of Insulation Coatings Semi organic Thin Coating A Improves Punching Performance and Has Good Weldability Semi organic Thick Coating H has Good Punching Performance and High Interlayer Resistance Semi organic Chromium Free Thin Coating K does not contain chromium and has good weldability Semi organic Chromium Free Thick Coating M does not contain chromium and has good insulation performance Semi organic Chromium Free Extreme Thick Coating J does not contain chromium and has excellent insulation performance Semi organic Chromium Free Ultra Thick Coating L does not contain chromium and has extremely high insulation performance Self adhesive Coating

鹿程国际贸易(德宏市分公司)秉承“精于设计,工于制造”理念,持续不断的进行 汽车钢产品研发,创新。提供非标准定制服务,可根据您的实际需求设计加工,量身定制。 具备完整的 汽车钢制造加工能力,确保 汽车钢产品即时规模生产、交货准时。

电工钢硅钢片本文件按照 GB/T 1.1—2020《标准化工作导则 部分:标准化文件的结构和起草规则》的规定起草。本文件代替 Q/BQB 485-2020。本文件与 Q/BQB 485-2020 相比,主要修改内容如下:— 新增了普通型 Q、附近高磁极化强度型 QG、附近磁畴细化型 RK 产品牌号;— 补充配电变压器专用和耐热刻痕磁畴细化两个类型产品;— 补充 B18P070、附近B20P075、附近B23P080、附近B27P085、附近B27P120、附近B30P090 六个高磁极化强度型产品和B18R055、附近B18R060、附近B20R060、附近B20R065、附近B23R070 五个磁畴细化型产品;— 依据 IEC 文件(IEC 6040-8-7 Edition 5.0 2020-09),对单片法(SST)磁性能检测数据转换规则进行调整;— 补充无 Cr 环保涂层产品相关规定;— 修改了钢带的浪高标准。请注意本文件的某些内容可能涉及 。本文件的发布机构不承担识别 的责任。本文件由宝山钢铁股份有限公司硅钢事业部和制造管理部提出。本文件由宝山钢铁股份有限公司硅钢事业部、附近制造管理部和武钢有限联合起草。本文件所代替的历次版本发布情况为:Q/BQB 485-2007,Q/BQB 485-2014,Q/BQB 485-2016,Q/BQB485-2018,Q/BQB 485-2020。